EPE and EPE foam Recycling

Expandable Polyethylene, EPE for short, is High Density Polyethylene (HDPE) compressed mainly from Low Density Polyethylene (LDPE) material. EPE has a higher elasticity and white appearance. Since it is complete independent bubble, it is light weight, flexible, bendable. Having improved ordinary polyfoam’s shortcomings of fragile and proteinform.EPE has the properties of warmth preservation, moisture prevention, thermal insulation, sound insulation, antifriction, anti-aging and corrosion resistance.

EPE is an environmentally friendly material which can be recycled. Plus its good chemical properties, it is an ideal substitution of traditional package material. EPE has been widely used in products package area, such as computer, electrical appliance, expensive furniture, leather products and so on. Especially slap-end art ware package, not only luxurious but also has good quake resistance protective effect. Developing towards high grade is the future trend of EPE package.Since EPE is a new environmentally friendly package material. Its superiority is gradually accepted by people, and its application is enlarging and innovating.As the increasing popularity and demand of EPE material, we should also pay attention to its recycling after using. Waste EPE is increasing, its enormous volume and light weight make it very inconvenient to transport.

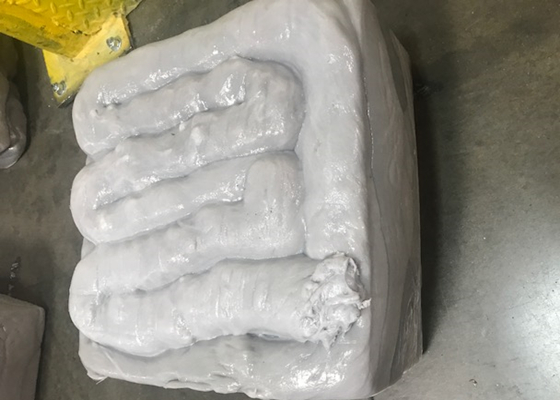

Luckily, our company INTCO Recycling can provide total solution to EPE recycling. Our product GREENMAX is an plastic foam recycling machine. GREENMAX offers two main technologies for EPE foam recycling - EPE foam compacting and EPE foam melting. The compacting technology reduces the size of the foam waste by compressing it, while the melting technology heats the EPE foam, causing it to melt and then cool into dense blocks.Both methods significantly reduce the volume of the EPE foam (up to a 90:1 ratio in some cases), which is crucial for efficient recycling. This reduction in volume makes it more economical to transport the material to recycling facilities or for further processing.

By converting bulky EPE foam into more manageable, compact forms, the GREENMAX system facilitates the recycling process. This is especially important for businesses that generate large amounts of EPE waste, like those in the packaging, automotive, or appliance industries.The compacted or melted blocks of EPE can then be sold to manufacturers who recycle them into new plastic products. This not only helps in reducing the environmental impact but also creates a circular economy where waste materials are given a new life.

By efficiently recycling EPE foam, the GREENMAX system helps businesses reduce their waste disposal costs and lowers the environmental impact associated with EPE foam waste.